TOPCON Technology: The next big thing in the Solar Market

TOPCON is the Tunnel Oxide Passivated Contact technology that Fraunhofer Solar Energy Institute Germany developed. It reduces the electron recombination rate at the surface, improving the cell’s overall efficiency.

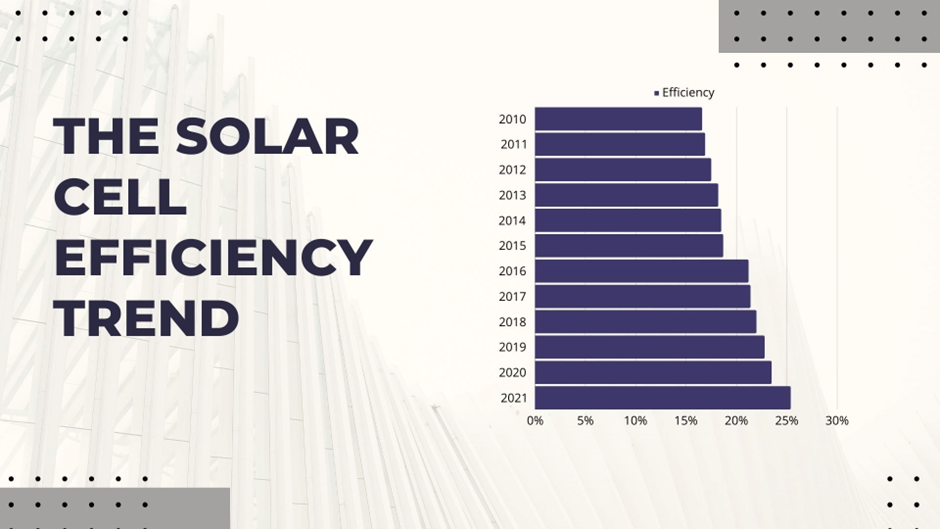

Technologies such as Mono-PERC, HJT, and Half-cut have enabled solar panels with efficiencies close to 22%.

Contact passivation is one such technique that improves the solar cell’s efficiency.

Traditional solar cells use metal contact to collect the current from the cell and transfer it to the load. However, these contacts have some surface area that blocks the sunlight from falling on the solar cell. Hence affecting the solar cell’s efficiency.

The TOPCON technology solves this problem by using a tunnel oxide between the cell and the metal contact that allows a clear path for the electrons to flow and reach the load. Hence, resulting in higher efficiency.

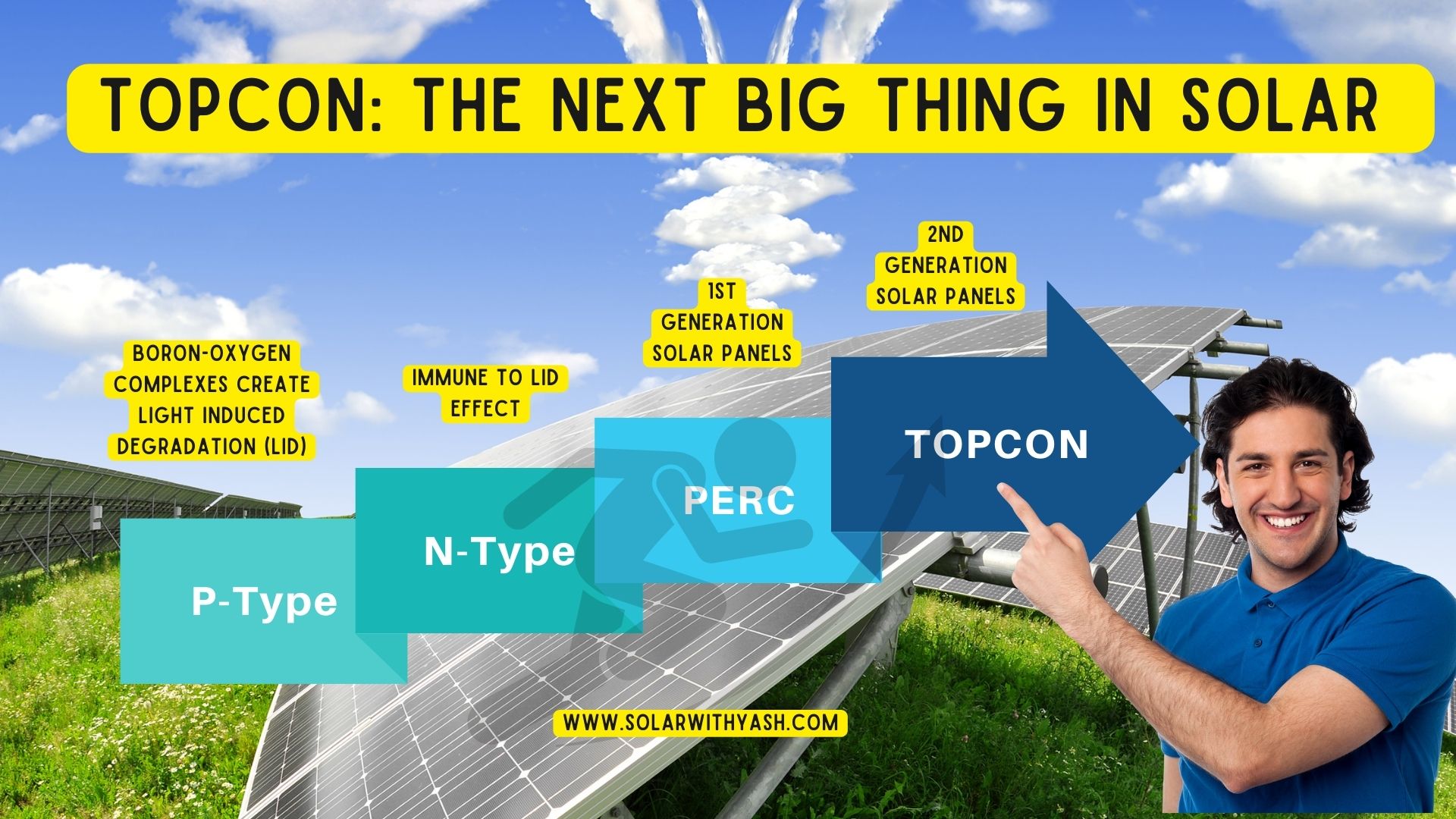

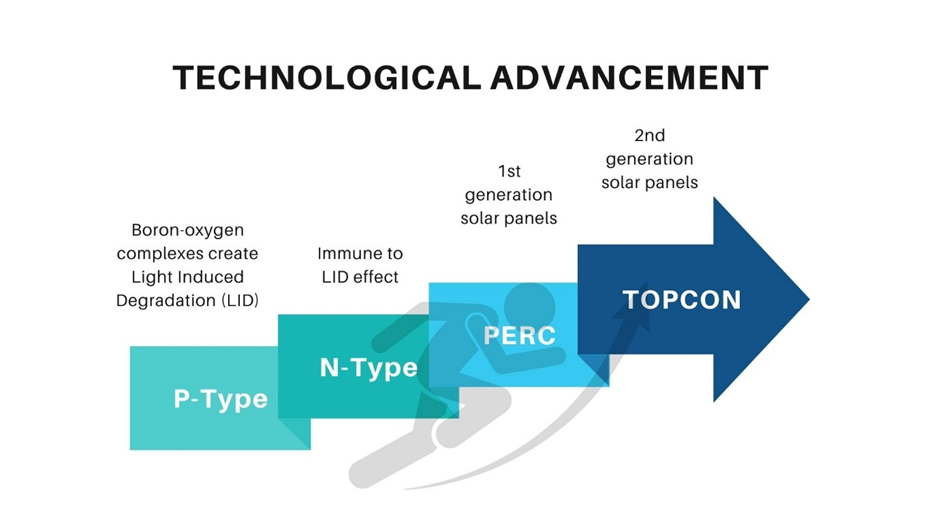

Let us see the technological and the efficiency advancement of solar cell

Efficiency

What is TOPCON Technology?

The TOPCON technology is based on the N-type cells.

(When the silicon cell is doped with a pentavalent impurity such as phosphorus, it becomes an N-type silicon cell.

In P-type cells, the silicon wafer is fused with trivalent impurities such as boron.

When the N-type and P-type silicon come in contact, they make a P-N junction which creates the electric field and develops the voltage across the ends of the junction.

In an N-type solar cell, the silicon wafer is N-type (doped with Phosphorus) and a thin layer of P-type silicon (doped with Boron) is fused over its surface to create a P-N junction.

The advantage of an N-type cell over a P-type is that it is more immune to degradation in sunlight. The N-type solar cell has a minimal quantity of Boron dopant. Therefore, it is immune to Boron-Oxygen complexes that form in the presence of sunlight).

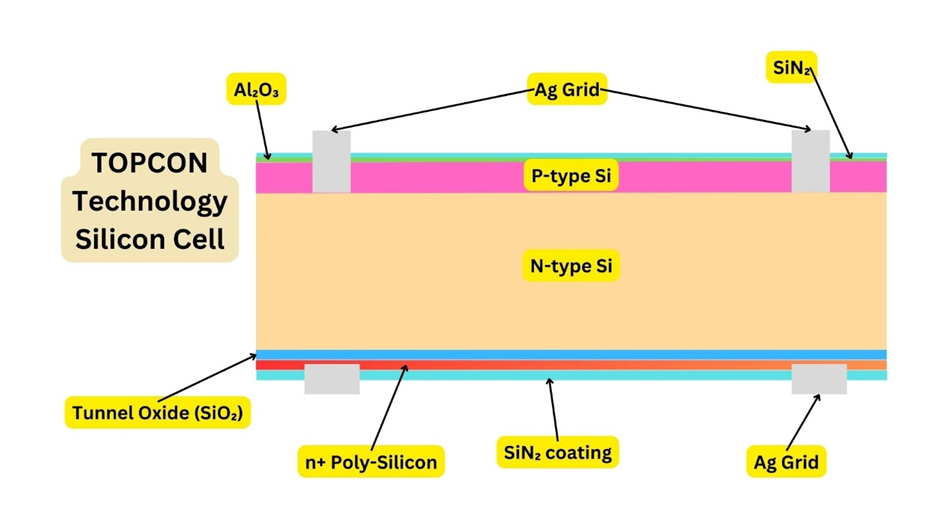

To make TOPCON cells, some additional layers are added to the N-type solar cell.

The tunnel-oxide (SiO₂), and the polysilicon layers are added at the back of the cell.

This improves the contact passivation, leading to a higher open circuit voltage and hence, improved cell efficiency.

What is Passivation?

Passivation is a technique of reducing the premature electron-hole recombination on the surface of the silicon wafer. This makes more electrons available for the current. Hence improving the efficiency of the cell.

(The silicon wafer is the basic raw material for making a solar cell. However, this wafer has some inherent defects which affect the performance of the solar cell.

The most prominent defect is the surface defect. It arises due to the disruption in the lattice structure of silicon at the surfaces when it is sliced from the ingot. This results in dangling bonds at the surface. The dangling bonds are a kind of free radicals which can recombine to whatever material they are exposed to. The passivation technique checks this defect and reduces this recombination. Hence safeguarding the cell’s efficiency).

This process improves the power production and hence the efficiency of the solar cell.

The TOPCON solar cell structure and working

When the sunlight falls on the surface of the solar cell, the electrons absorb it and get excited. They then jump from the valance band to the conduction band. Now the electrons are free to move and conduct.

This leaves a hole (positive charge) in the valance band.

These photo-generated electrons cross the PN junction and reach the N-type region. Thereafter they move to the bottom of the N-type region.

The holes present at the bottom of the N-type are ready to recombine these free electrons.

Here comes the TOPCON technology concept.

The thin layer of SiO₂ acts as a tunnel for these free electrons allowing them to pass through and preventing the hole (positive ions) from entering. Hence prevents the electrons-holes recombination.

Thereafter, the n+ polysilicon creates an electric field which further attracts the electrons and repels the holes.

Finally, the high numbers of free electrons reach the silver (Ag grid) contacts where interconnected ribbons collect them and then send them to the external load.

We can upgrade the Mono-PERC to TOPCON technology by changing the P-type to N-type substrate and adding the tunneling passivation layer.

But

This requires more capital investment than the other technologies in the market.

Manufacturing process of TOPCON solar cell

The first step is to make the silicon wafer defect-free. This can be achieved either by chemical passivation or field-effect passivation.

We will discuss chemical passivation in this post.

- In chemical passivation, the chemical is used to saturate the dangling bonds (satisfy or pacify them by providing free electrons) at the surface of the silicon wafer.

- Boron diffusion: After cleaning the wafer, the diffusion technique is used to grow an emitter on the front side of the wafer.

- Tunnel Oxide Growth: The ultra-thin layer of silicon oxide (dielectric layer) is grown at the back through wet chemical dipping.

- Doped Poly-Si deposition & Annealing: Thereafter, the phosphorus-doped amorphous silicon layer is deposited through Plasma Enhanced Chemical Vapor Deposition (PECVD). It becomes an n+ Poly-Si layer at 900 degrees.

- Front and rear di-electric deposition: Then Silicon-nitride layers are applied and finally silver contacts are fixed using a quick firing method at 700-800 degrees.

Advantages of TOPCON Technology

This technology offers many advantages over its conventional counterparts.

1. Higher Efficiency

Compared to the conventional solar cells in the market, the TOPCON solar cells are more efficient in converting sunlight into electricity. The maximum efficiency of TOPCON-based solar cells is over 26%.

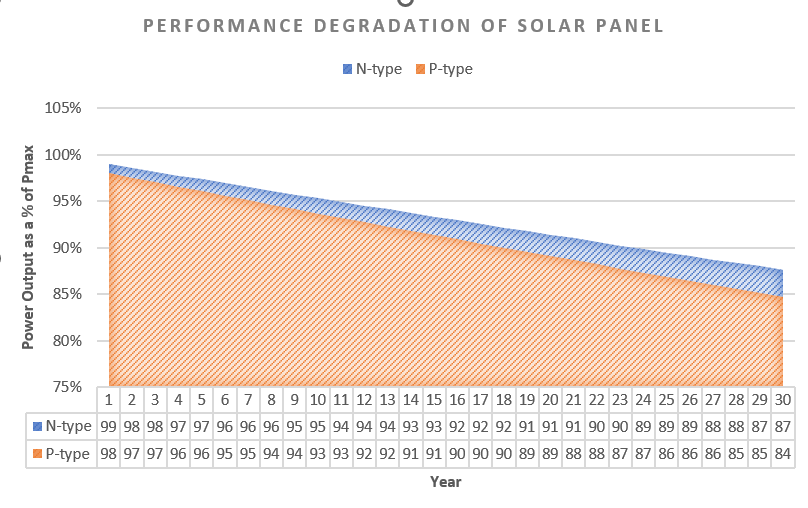

2. Lower Degradation

The TOPCON solar panels are based on the N-type solar cell which are more immune to the light-induced degradation (LID) effect.

Unlike their P-type counterparts, the TOPCON solar panels do not form boron-oxygen complexes (which inhibit the PV effect) in the presence of sunlight. In comparison to conventional solar panels, the TOPCON solar panels degrade very little in the first year and also in the remaining operational life.

3. Lower Temperature Coefficient of Power

The output of the solar panels deteriorates when their cell temperature increases beyond 25ᵒ. How much power a solar panel will lose is indicated by its temperature coefficient of power. The lower the value of this metric, the less the power loss with temperature rise.

The traditional solar panels have this metric close to 0.4%/ᵒC. The TOPCON solar panels have a temperature coefficient of power of less than 0.3%/ᵒC which makes them lose 25% less power than their traditional counterparts.

The TOPCON solar panels can prove to be a great energy option for people living in hot climates.

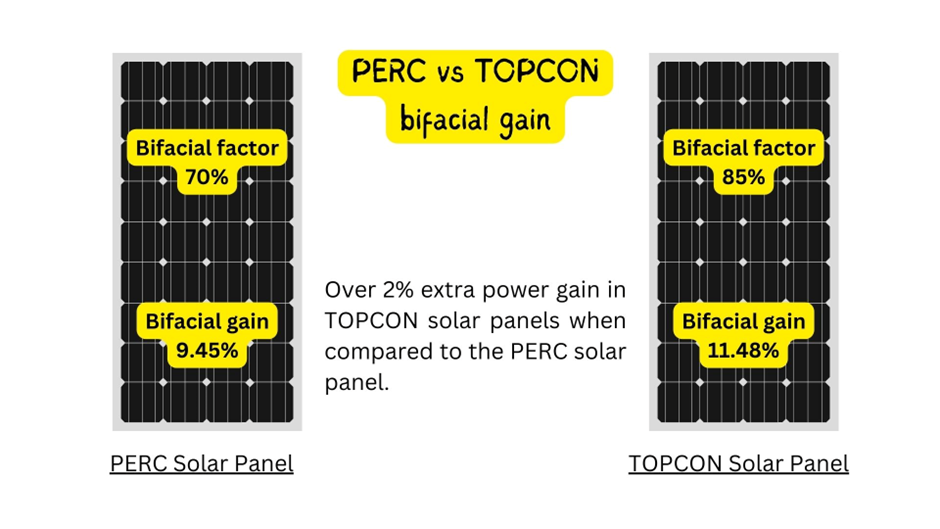

4. Better Bifacial Performance

The bi-facial factor of the TOPCON solar panels is up to 85%. While PERC solar panels have 70%.

This 15% increase in the bifacial gain gives 2% more power gain than the PERC bi-facial solar panels.

5. Improved Low Light Performance

Due to their high efficiency, they are capable of generating enough power even in low-light conditions.

6. Better Performance Warranty

The TOPCON solar panels have better performance over 30 years than the conventional P-type solar panels. Their power degradation is less than 1% in the first year (less light-induced degradation than the P-type solar panels due to less boron-oxygen complex formation).

The TOPCON solar panels are guaranteed to produce at least 87% of their P(max) even in the 30th year.

7. Similar Production Line

One of the great things about TOPCON technology solar panels is that their manufacturing process is similar to that of PERC solar panels.

With little investment, you can upgrade the existing production line for making the TOPCON solar panels. This aspect is making TOPCON technology a financially attractive option in the solar market.

How is TOPCON Technology different from PERC Technology?

It is different in terms of production process, contact design, efficiency, cost, and the temperature coefficient of power.

The Mono-PERC has the Passivated contact on the front side while the TOPCON has this on its rear side.

The PERC solar cells are manufactured by covering n-type crystalline silicon with a p⁺emitter layer to create a p-n junction.

Then this emitter layer is covered with Aluminum oxide (Al₂O₃) as a passivating layer (to reduce the recombination rate at the surface).

Thereafter, this layer is covered with Silicon nitride (SiNx) as it has anti-reflection properties.

The bottom of n-type crystalline silicon (bulk layer) is doped with phosphorous to create a back surface field and it is then covered with SiNx as done at the top surface.

Finally, both the top and the bottom of the cell are covered with silver contacts to complete the circuit when the cell is connected to the load.

The TOPCON is the extension of the PERC technology. The basic structure remains the same but it includes a tunnel oxide (silicon oxide) at the back of the bulk silicon and replaces the back surface field layer with n⁺ Poly-Si.

These modifications further reduce the recombination rate⁺ and improve the efficiency and open circuit voltage of the cell.

TOPCON has a higher efficiency exceeding 25% while the Mono-PERC has the highest efficiency of 23%.

The manufacturing of the TOPCON cell requires additional steps in the production line due to the passivation of its rear side.

While in Mono-PERC, it has evolved from traditional manufacturing. Hence it is more cost effective than TOPCON.

Top TOPCON Solar Panel Companies

- LONGi

- Trina

- Jinko

- Jolywood

- Fraunhofer-ISE

- Hanwha Q-cells

- Canadian solar

- REC Solar

- RENA technologies GmbH

- AE solar

Challenges for TOPCON Technology

- The TOPCON solar cell requires a good amount of silver to make contact with the cell. The increased use of silver leads to the higher manufacturing cost when compared to the PERC technology.

- Another challenge is to keep the Passivation technique effective at higher temperatures. To make the contacts fused properly with the solar cell, a high temperature is required.

- However, this may lead to oxide breakage, and the recombination rate increases, reducing the efficiency of the cell. Therefore, a trade-off is achieved between the efficiency and the open circuit voltage of the solar cell.

Conclusion

Recently, Jinko Solar also announced that it has achieved a maximum solar cell conversion efficiency of 26.89% of its 182 mm N-type monocrystalline TOPCON solar cell.

The solar industry is in the transition phase towards the latest N-type technologies such as TOPCON, HJT, and IBC.

The HJT and IBC are also very interesting and amazing technologies with very high efficiencies.

But they require new production lines, increasing the manufacturing cost. Hence affecting their financial feasibility.

Whereas TOPCON technology can be developed with slight modifications to the existing PERC solar cell production line. Hence, they are more financially attractive. Looking at the present trend there is a high probability that the TOPCON solar panels will rule the solar market in the future.

To be continued…