What are the benefits of half-cut solar cell technology?

I wrote in my previous post that how PERC Solar Cell Technology resulted in the increase in efficiency when an extra layer is pasted at the back of the solar cell.

Another technology that has come into the mainstream is Half-cut Solar Cell technology.

This technology improves the efficiency of the solar panel and gives a boost in its power output.

You see the traditional solar panels having 60-cells or 72 cells solar cells,

but

once half-cut technology is implemented, these become 120 half-cut cells or 144 half-cut cells solar modules.

What is half-cut solar cell technology?

As the name suggests, the traditional silicon solar cells are cut into halves that improve efficiency.

In addition to this,

the half-cut solar cells are now more durable and become resistant to cracking because of their small size.

And

the half-cut solar cell technology is even more worthwhile for people that are having space constraints and shading is a problem.

Moreover, this also improves the financial feasibility of the Solar Power System for a person that has installed Half-cut solar cells-based solar panels.

It is because of these advantages, the Half-cut Solar Technology is getting popular in the solar market and is gaining market share with acceleration.

Let’s discuss more, how it improves the performance and the durability of the solar panels?

Benefits of half-cut solar cell technology in solar panels

Let us discuss the advantages of using half-cell technology in solar panels.

1) Reduction in heat losses

When the sunlight falls on the surface of the solar panel, the interconnected solar cells within the module convert it into electricity.

We all know that not all the sunlight is converted into electricity.

We call it a conversion loss.

This electric current produced by the cells flows through the strips or wires that connect them together.

In this process, some of the electric energy is dissipated as loss in the form of heat energy.

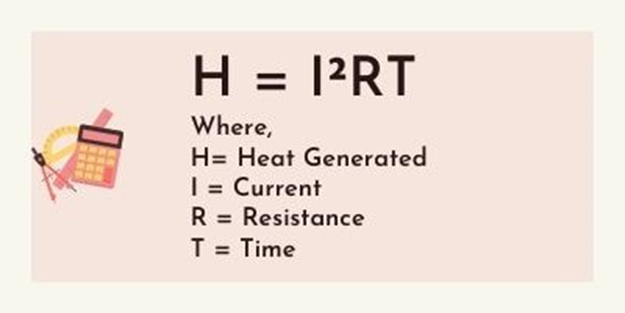

The amount of heat loss is directly proportional to the square of the current flowing in the solar cells.

If I keep Resistance and Time constant

Then

If the current is 2 units, the heat generated would be (2)² = 4 units

When the current is 3 units, the heat generated would be (3)² = 9 units

In simple words, the heat generated is a square of the current flowing in the solar cells.

More current means even more heat loss.

If I cut the 1cm² solar cell in 2 halves and then connect them in series, the current production will also reduce to half.

It means, the heat loss is reduced to one-fourth (1/4) of what it was when the cell was complete.

That saved heat loss is converted into an equivalent amount of useful power for running our electrical appliances.

The half-cut solar cell technology uses this concept and when you implement this you get more efficient solar panels.

2) Increase in structural strength

The material strength is random and the strength of the weakest part of the solar cell further decreases with the increase in its size.

And

any stress in that part can create serious flaws in its working and can even break it down even before its maximum load strength is reached.

When we reduce the size of the solar cell, the chances of cracking are reduced and increase the overall strength of the cell.

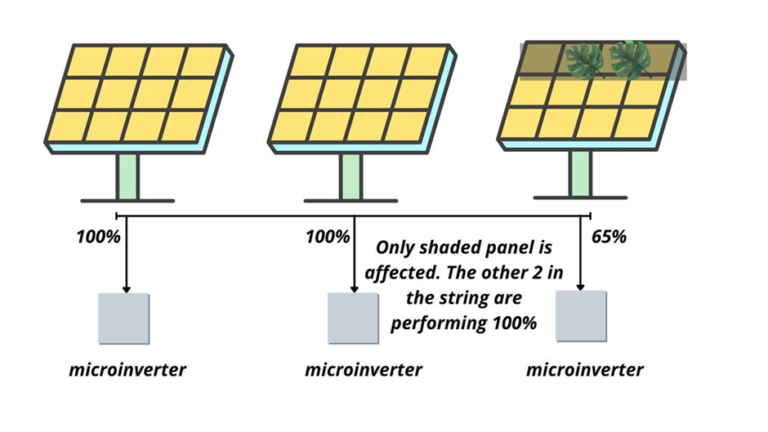

3) More shade tolerance

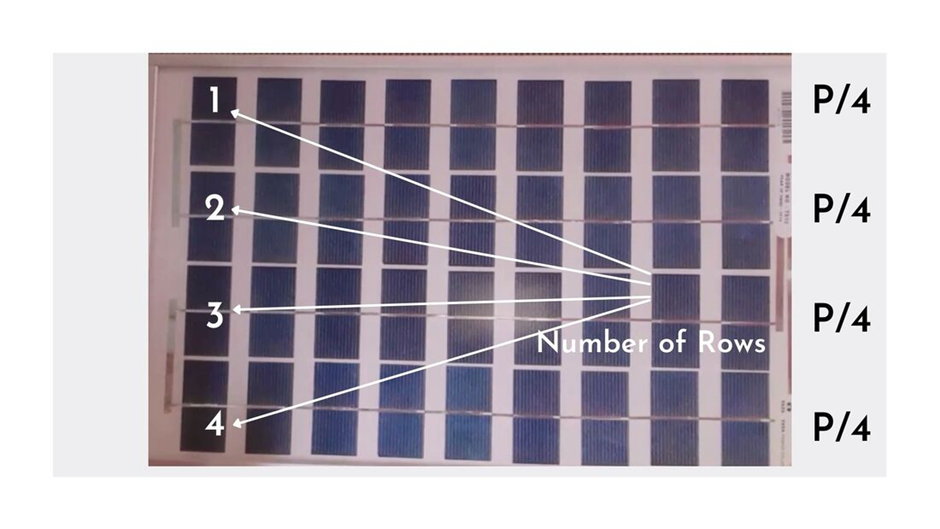

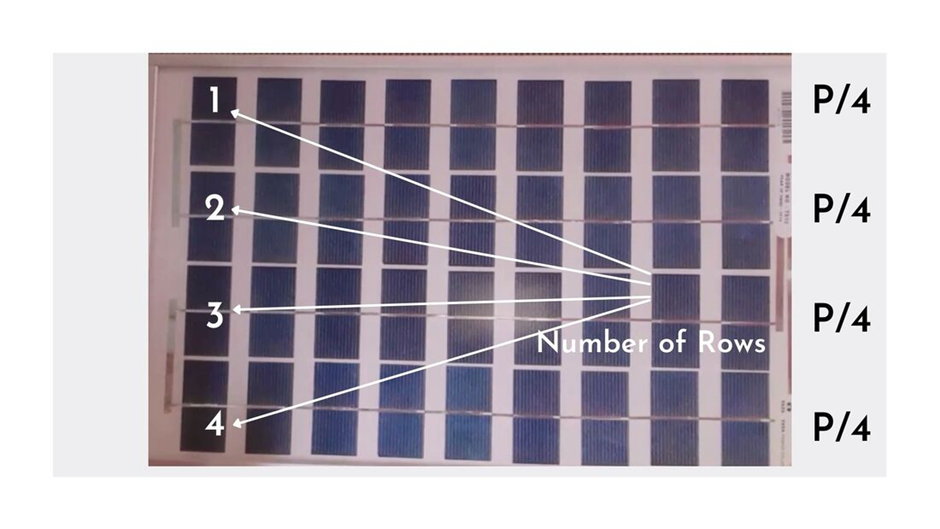

Look at the front of the solar panel, you’ll notice that solar cells are arranged in a certain fashion called Rows.

There are 4 rows in the above panel and each row is having 9 solar cells connected in series.

A total of 4 x 9 = 36 cells in the solar panel.

(while any 2 rows can either be connected in series or parallel depending on what kind of voltage the manufacturer wants to generate from the solar panel.)

The number of solar cells in each row is the same. Therefore, the power produced by each will also be the same.

That is P/4 by each row if the total power of the solar panel is P watts.

If any 1 solar cell in any of the 4 rows is shaded then the whole string is affected.

You can see that if the second-last cell of the first string/row is completely shaded, the power output of the whole row is affected and reduced to zero.

Now, your solar panel is producing 3/4 P and P/4 power is lost.

Now,

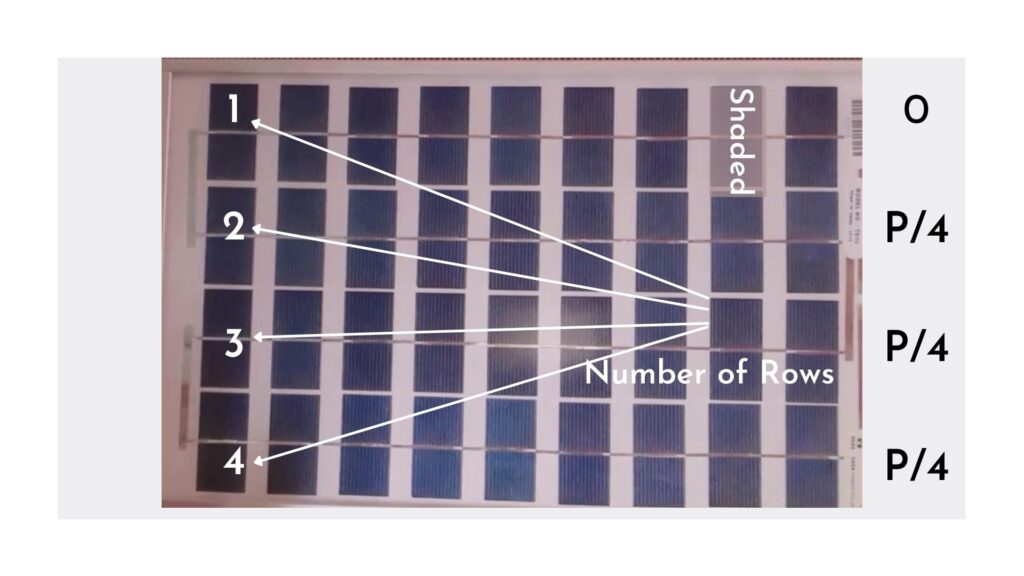

if I cut each cell in 2 halves, I’ll be having 2 x 36 = 72 half-cut solar cells.

And

the number of rows will also be doubled to 8.

Now each row is having 9 half-cut solar cells connected in series that are producing P/8 of the total power of the solar panel.

If any of the half-cut cells in any row is completely shaded, the power loss would be P/8 instead of P/4 that we saw when the solar cells were complete.

In this way, the half-cut solar cells technology helps reduce the shading loss.

Top companies manufacturing half-cut solar panels

The solar cells are brittle and can be cut using a laser.

The existing manufacturers do not need to change the production line to produce half-cut solar cell modules.

They can do it by adding 2 more steps in their production line one is laser cutting of the solar cells and then connecting them with strips into a string.

Cost benefit analysis

Let me give one simple cost-benefit analysis technique.

When the percentage increase in the efficiency is more than the percentage increase in price that you’re going to pay for the half-cut solar cell panels then it is profitable to go for this type of solar panel technology.

Or

you can try the solar feasibility spreadsheet to size and find the payback of the solar power system.

The half-cut solar cell technology solar panels are recommended for those homeowners having space constraints and where the roof is shaded at least once a day due to nearby buildings, trees, or any other nearby constructions.